Solutions for M&A activity and regulatory compliance updates

As most of our gas consumers recover to 100% productivity again, ‘go-to production’ timelines become more challenging when supplies do not arrive in time before they have already scheduled their production runs. And as gas consumers and manufacturers scale up production again, knowing supplier lead times become much more crucial. Relying on JIT (Just-In-Time) supply chain today is becoming a huge challenge. Late supplier deliveries are starting to impact both time and material allocations and their limited warehouse space among other issues for manufacturers. In turn, affecting their bottom-line.

So how does this relate to Gas Suppliers & Distributors? Because most of these types of vertical markets are gas consumers relating to welding gases, CO2 carbonation, food preservation, and ingredient extraction solutions, etc.

With more expected stop/start demand growth from both the industrial manufacturers and medical gas customers for the next couple of years, the higher the supplier delivery demand will be for most aspects of the compressed gas industry. This includes core gas supplies, accessory parts, plant equipment, and related services. And with higher industrial manufacturing demand, it could mean that gas suppliers and distributors will need to buy more bulk supplies up front to help offset high demand. The point here, is that business processes and operations efficiency become even

more important, no matter the size of the company for both gas suppliers and distributors in this new era.

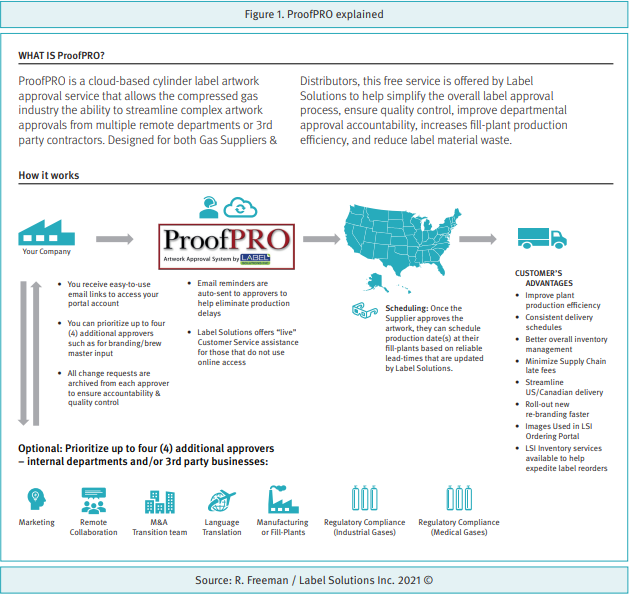

One way Label Solutions has approached this ‘efficiency’ need to help the gas industry, is by offering our new ProofPRO Artwork Approval Service. ProofPRO is a cloud-based cylinder label artwork approval service that allows the compressed gas industry the ability to streamline complex branding and/or regulatory compliant artwork approvals from multiple remote departments or third party contractors… no matter if they are located at remote offices in North America or around the globe.

Designed for both gas suppliers and distributors, this free service is offered exclusively by Label Solutions to help simplify the overall label approval process, ensure quality control, improve departmental approval accountability, increases fill-plant production efficiency, and reduce label material waste. One important benefit to using ProofPRO is that it allows either one or up to five prioritized label artwork approvers to view, modify, notate, and visually proof each cylinder label from remote locations via web browser link to a password protected portal.

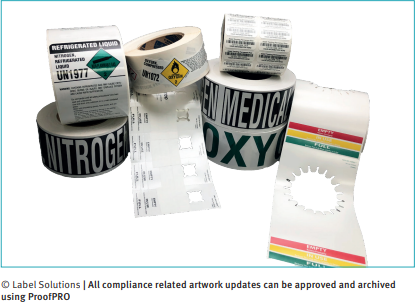

Users can view each artwork file electronically. Including label content, color gamut related to their branding guidelines, and manage OSHA and DOT regulatory compliant related content changes for each industrial and/or medical cylinder label. The same approval process can be applied to larger wide-format signage such as upright bulk tank signage and

fleet signage.

ProofPRO can archive user notation and comments to ensure accuracy and approver accountability. What is more, notes and approval dates can be retrieved at request for

historical reporting to ProofPRO authorized users.

Another example of a benefit in today’s compressed gas industry includes M&A (Merger & Acquisition) Transitions. If the gas industry continues to consolidate, corporations can begin their rebranding initiatives based on merger or acquisition deadlines prior to (or soon after) their public announcement. This ProofPRO solution can include the ‘acquiring’ company’s marketing team planning their new branding on the ‘purchased’ company’s tanks, cylinders, and bulk tank signage much more efficiently and sometimes even faster if planned correctly.

For example, the M&A project leader can include up to four (4) additional artwork approvers. This can include individuals from the M&A transition team, regulatory compliance departments (industrial or medical), language translation contractor, and/or C-Level marketing management headquartered in Europe.

The efficiency behind this solution is that the project leader can prioritize approvers, auto-send approval reminders to their other approvers to help ensure completing due dates. Also, if newly branded labels need to be tested before a large production run can be scheduled, the project leader will be notified via email that their last approver has completed the artwork approval. The project leader can then contact Label Solutions to get a more accurate lead-time date to schedule future production line testing or go-ahead place their order of the newly branded labels to replace the inventory at the acquired locations.

This not only helps our customers during the label approval process, but it also benefits Label Solutions too because it builds a safety factor between last-minute changes from the customer and our production team… so we do not produce the labels too early. Thus, helping Label Solutions reduce any unnecessary material waste. Since this is a ‘win-win for both Label Solutions and their customers, it is one of the reasons why we do not charge for this service.

Other examples of how ProofPRO works are listed in the (Figure 1) diagram above. Understanding how this can be used can be extremely beneficial for ProofPRO users. This can be as simple as only one person streamlining their artwork approval or have the capability to invite other departments that are associated to the contents of a more complex cylinder label when necessary.

A list of customer advantages using ProofPRO can be found on the diagram. Some of the key advantages include better overall material handling, more consistent supplier deliveries, and can often help minimize Supply Chain late delivery fees. Customers in other industries using ProofPRO continue to find new ways that benefit their production times such as rebranding projects, working with third party marketing firms, and for private labeling applications.

ABOUT THE AUTHOR

Rob Freeman is the Vice-President of Revenue Operations at Label Solutions Inc., which specializes in producing product labels for the compressed gas industry, industrial manufacturers, food and beverage, health and wellness, and nutraceutical markets. Rob manages Label Solutions’ Marketing, Business Development, and Customer Service departments, as well as their key accounts in North America.