Help During the COVID-19 Pandemic

The Label Solutions family hopes you and your loved ones are safe and healthy during this trying time. Many products are in high demand right now in response to the Coronavirus (COVID-19) outbreak and pandemic, many of which consumers are having a hard time finding on store shelves.

We can help put items in the hands of those who need it most. Our professional team offers expedited printing services for a wide range of custom labels, including ones for:

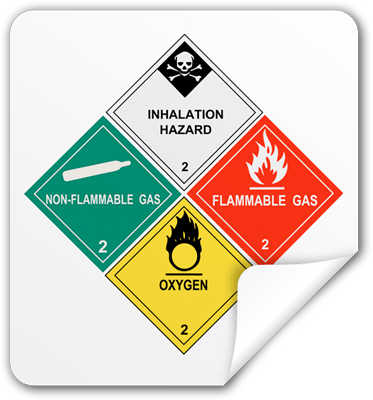

- Medical oxygen tanks

- Hand sanitizer

- Hydrogen peroxide

- EPA-registered disinfectants

- Isopropyl alcohol

- Nutraceuticals

- Dietary supplements

- Immune support supplements

Contact us now to request a quote, whether you need a big project with multiple sequential barcodes or high-quality gas cylinder labels for medical oxygen tanks. We can expedite your order if you need it now.

Full-Service Custom Labeling

There are hundreds of thousands of labels fighting for the spotlight. The only way your label is going to stand out from the rest is to make it not only functional but exciting. That's what we do. We have the capability to create must-see artwork for your label and offer a variety of printing options, including digital printing, flexographic printing, and wide format printing.

Label Solutions is a full-service labeling company. From morning till night, we focus on creating innovative labels that are crisp, clean, unique and functional. Our full-service capabilities allow us to fulfill your order quickly and efficiently—and when last minute changes arise—we are able to go with the flow.

Whether it's a warning label for an industrial cylinder product or an ingredient listing for food and beverage products. Want your wine bottle to be the focal point on the store shelf? We can make it dazzle with our full-color printing processes. Need a label that will hold up in negative 32-degree temperature? No problem, we've got labels that will handle all types of temperatures. Looking for something that is more than just a label? We developed Tags on a Roll®, a product so unique it's patented!

We're a Women's Business Enterprise!

Label Solutions is proud to be a Women's Business Enterprise as certified by the Women's Enterprise National Council (WBENC). Company president Karen Stevens was instrumental in achieving the WBE distinction for companies in Southwest Missouri as a women-led or women-owned business. Request our WBE Certificate today if you're interested in our diversity monitoring data to help us improve our HR processes.