White and clear BOPP labels are one of our most durable and popular products for the consumer packaged goods (CPG) industry. Biaxially oriented polypropylene is a low-cost material used not only in labels but also in shrink wrap for food packaging. In today’s blog from Label Solutions, we examine why white and clear BOPP labels are so popular with CPGs.

Related Post: Label Solutions Compares Vinyl and BOPP Labels

The “No Label” Look

Many CPG brands rely on visual presentations to make their products more appealing to consumers. Clear BOPP labels provide a “no label” look for brands when visual appeal is a must. Think of candies, cookies, meats, prepared salads, and fresh fruits. Much like consumers look at photos on restaurant menus to order food, the same is true for CPGs. They want to see that the fruit is ripe, the vegetables are crisp, and the cookies have lots of chocolate chips. Items that have a distinct color also benefit from clear BOPP because those colors will stand out among other products on the shelf.

Flatness

White and clear BOPP labels are flat, which means they conform well to containers. This is particularly true for items that aren’t necessarily uniform in shape, such as fresh meats, or unusually shaped packages such as spheres. White and clear BOPP labels can fit on just about any product package you can imagine.

Oil & Water Resistance

Both white and clear BOPP labels offer oil and water resistance. Salad dressings, juices, packaged fruits and vegetables, herbs and spices, honey, and personal care items that go in the bathroom all benefit from having BOPP labels. Items that go in the garage, such as paints, motor oil, and grease, are also great candidates for these labels.

Low Toxicity

The low toxicity of white and clear BOPP labels make them ideal for CPG brands with regard to food. Polypropylene is a sturdy material that doesn’t seep into other items or onto people’s hands. BOPP is made from FDA-approved resins, so it’s safe to use on CPGs.

Superior Strength

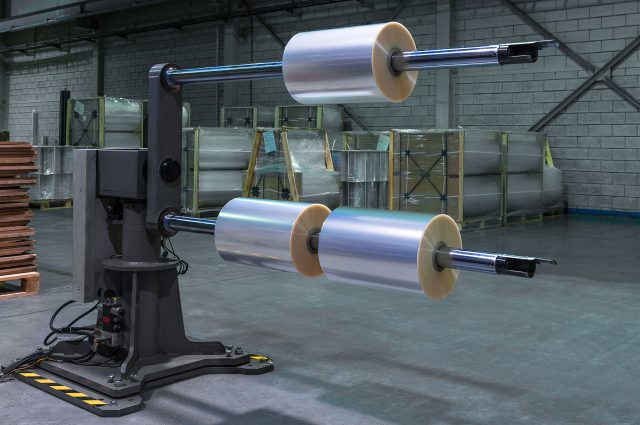

BOPP is made by mechanically stretching a clear film in the machine direction and the transverse direction (hence the name, “biaxially oriented”). This process creates a stronger product compared to cellophane or similar materials. The manufacturing process also allows for cheaper materials costs.

Low Costs

Items made of BOPP have been around since at least the early 1980s. Because of nearly 40 years of investment by large companies in this substance, white and clear BOPP labels are an industry standard that can lower your costs as a CPG brand. Combine the low cost of BOPP with a professional labeling company, and your products receive a boost when vying for attention on store shelves in the highly competitive CPG space.

Related Post: Why Is BOPP a Great Material for Labels?

White and Clear BOPP Labels From Label Solutions

Label Solutions is one of the top producers of product labels in the country. We serve many industries with custom labels that look great, comply with regulations, and improve your time to market. Contact Label Solutions today or call toll-free 1-800-299-9200 for more details on our white and clear BOPP labels.