Label Solutions produces commercial labels for a wide range of companies, including industrial labels for manufacturers and products that must stand up to harsh conditions.

Today, our experts answer several frequently asked questions about industrial labels.

What is an industrial label?

Companies use industrial labels to comply with safety regulations, track assets throughout the supply chain, and identify products. Industrial labels are made to withstand harsh conditions, extreme weather, and long-term storage.

What industries use labels?

A wide range of companies utilize industrial labels, such as:

- Manufacturers

- Petroleum producers and sellers

- Utilities

- Healthcare providers

- Transportation and logistics firms

- Automotive manufacturers and suppliers

- Original equipment manufacturers (OEM)

- Construction firms

- Consumer durable goods companies

- Hardware manufacturers

Why do companies need industrial labels?

They serve several purposes, including:

- Warning people of possible dangers

- Listing the contents of a package or room

- Identifying parts, equipment and assets

- Withstanding logistics, shipping, and handling

- Resisting heat, moisture, and extreme temperatures

- Branding and marking of packages

- Performing quality control

- Assessing inventory

- Facilitating returns or recalls

- Organizing shipments and parts

- Packaging products

What are industrial labels made of?

Depending on your company’s needs, you might need labels made of:

- Polyester

- Plastic

- Vinyl

- Polyimide

- BOPP (biaxially oriented polypropylene)

How do label producers create industrial labels?

A commercial label supplier creates them using a comprehensive process:

Initial consultation. Once you begin the conversation, your industrial label supplier will talk to you about your team’s requirements. We’ll discuss how many labels you need, what substrate they are going on, the dimensions, and what products you need them for. All of these factors go into a custom production run.

Label design. If needed, a commercial label supplier can work with you to design the most effective labels using cloud-based software such as ProofPRO to allow you to make tweaks and changes. Once your team approves the design, it’s time for production.

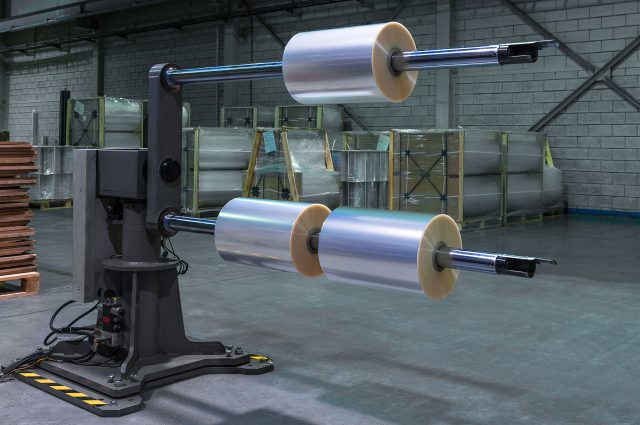

Label printing. The beauty of modern technology is that most industrial labels are printed digitally rather than through traditional methods of plates to transfer images. Blank labels typically go through the machine in a long roll. Along the way, our team makes sure each run conforms to your quality standards.

Finishing. Some labels get a finishing process, such as embossing, stamping, varnishing, or laminating.

Die-cutting. If you need labels cut a certain way, a commercial label supplier can die-cut the labels to prepare them for your label applicator. Or you might need them to stay in a roll for easy application, depending on your machine.

Why make industrial labels out of polyester?

Polyester labels protect against weather and water because of their high resistance to smearing, peeling, and tearing in harsh weather and storage conditions. This material also resists chemical reactions.

Why should I use vinyl for my industrial labels?

Vinyl is a flexible material that works well when you have curved surfaces and need strong adhesion. In harsh environments, you might need a laminate to go over it for protection from moisture and chemicals.

Why use plastic for industrial labels?

Plastic labels offer a cost-effective alternative to polyester and vinyl, so long as you select the right material and adhesive to bond with the right substrate for maximum usefulness. Plastic labels deliver outstanding results for resisting extreme temperatures, weather conditions, shipping, handling, and chemicals.

What is polyimide for industrial labels?

Polyimide is a high-performance plastic that resists heat. The electronics industry uses industrial labels made of this substance due to their stability and chemical-resistant properties as well as resistance to heat generated by electricity.

Why do I need BOPP for industrial labels?

BOPP (biaxially oriented polypropylene) provides strength against tearing because the production process stretches BOPP film in two directions. This allows for a transparent label that lets background colors show through. BOPP also resists water, oil, and chemicals better than paper does. So if your company needs labels that act like paper but resist things that paper can’t, BOPP is an option.

Can I mark or write on waterproof industrial labels?

Yes, you can write with permanent markers that don’t wear off easily. Waterproof industrial labels are made using laserjet technology rather than inkjets to prevent smudging.

What five things might appear on a warning label for industrial use?

There are five different types of notifications that appear on warning labels used in an industrial setting:

- Danger, which indicates some interaction or action will result in serious injury or death.

- Warning, which highlights that an action or interaction could result in serious injury or death.

- Caution, indicating something could result in minor or moderate injuries if the warning isn’t adhered to.

- Notice, or verbiage not used for hazards but only for informational purposes.

- General safety, which outlines safety procedures, safe handling instructions, or operating instructions for equipment.

In some cases, various warnings on industrial labels must follow certain protocols and regulations in terms of color, verbiage, numbering, and more. One prime example includes OSHA’s communication standards for labels and pictograms for chemical or hazardous materials containers.

What industries face regulatory compliance standards for labels?

Some industries face regulatory compliance for labels due to possible warnings, health hazards, and environmental hazards associated with the products, including:

- Consumer goods

- Automotive

- Industrial

- Chemical

- Electronics

- Security

- Agriculture

- Healthcare

- Pharmaceuticals

- Nutraceuticals

- Transportation

- Petroleum

As such, industrial labels for these products must meet strict requirements before being affixed to packages and products.

How does the Global Harmonization System regulate industrial labels?

The GHS handles worldwide regulatory compliance for communicating hazard information as laid out by OSHA under HazCom 2012. These labels tell workers and handlers what to expect with certain hazards, and inform emergency crews responding to accidents during transport or at a facility.

The GHS utilizes pictograms versus words to warn anyone what hazards may happen if there is a spill, explosion, or leak of the hazardous substance. Industrial labels must meet GHS protocols when they denote containers that harbor hazardous substances.

Why should I hire a commercial label producer for industrial labels?

Industrial companies should hire a commercial label production company because they are a team of experienced professionals who can help you design and create compliant labels that meet government standards and your exact requirements. Label Solutions can help you with your industrial label needs. Contact us or call 1-800-299-9200 for more information on partnering with our team.