by Rob Freeman, Director of Business Development and Marketing

In October I attended Gasworld’s North American Carbon Dioxide (CO2) Gas Summit in Indianapolis, Indiana. The small conference was packed with a high percentage of decision-makers in the compressed gas industry from around the world. It was an impressive gathering, and the topics discussed were very informative.

I had the opportunity to meet quite a few executives during the event. One of which was reporter, Paul Ericksen, from IndustryWeek.com. We spoke about a number of topics relating to the compressed gas industry.

Paul recently published his article, “More Boeing Hypocrisy—and Suppliers Will Feel the Fallout”, published on IndustryWeek.com on November 22, 2019. Paul took the time to understand what manufacturers go through when managing their regulatory compliant product labels, orders, and delivery times. Below is an excerpt from Mr. Ericksen’s article:

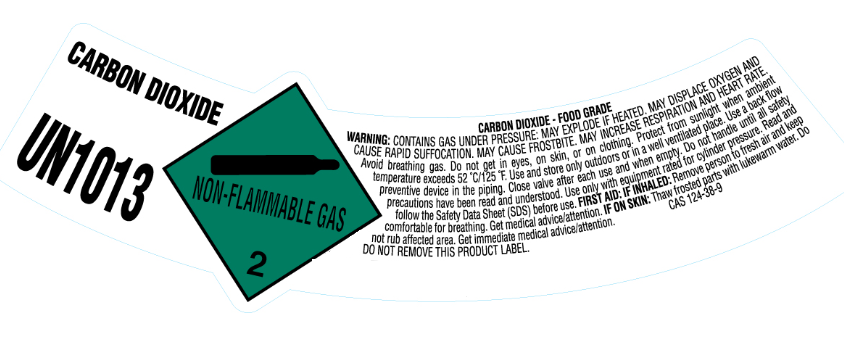

…You may be familiar with labels and barcoding as used in factories and everyday commerce. In the CO2 industry, however, product and process identification take on a significantly higher role. Why? The extremely low storage temperatures involved make this a dangerous industry for anyone involved in distribution. In fact, there are extreme standards and regulations relative to CO2 distribution overseen by OSHA and the Department of Transportation (DOT).

Additionally, there is an important difference between CO2 labeling and labels used in everyday commerce. Specifically, equipment used in product CO2 storage and distribution have long lives. As a result of this—as opposed to labels as they are typically used in factories—decals in distribution are subjected to significant, almost unending, material handling, throughout the supply chain; i.e. they are used as a form of “returnable container.” For this reason, the decals applied to these products must be robust. This implies being resistant to extreme fluctuations in temperature, being waterproof, having the ability to avoid condensation flux, fading and/or the loss of adhesion.

Why? In addition to safety and identification issues, the gas industry is highly regulated, meaning that should OSHA or DOT find a lack of—or damaged—decal, there can be significant fines. Because of this, it makes a lot of sense for a distributor of CO2 (or other gas) to put a high emphasis on the decals they use. In other words, price should not be the primary consideration when distributors source their decals. Click here to read the original article.

Your Solution for Durable Labels

For more information about what types of durable labels we produce for manufacturers go to easylabeling.com. Contact Rob Freeman at Toll-Free at (800) 299-9200 or email him at rfreeman@easylabeling.com. Label Solutions Inc. © 2019.